Capitol Tunneling offers extensive experience in both conventional and machine mined tunneling. Conventional tunneling, also known as hand mine tunneling, is commonly used to tunnel through soil, rock and fill. Tunnel installations using the hand mining methods are ideal for shorter, smaller diameter tunnels that don’t justify the expense of mobilizing a larger scale Tunnel Boring Machine to perform the work. Often, we still utilize specialized hydraulic tunneling shields to provide shoring and safety to both the traveling public as well as the hard working Capitol Tunneling employees diligently working to drive the tunnel. Since its inception, Capitol Tunneling crews have installed more than 125,000 feet of hand-mine tunnel, ranging from 4 feet to 18 feet in diameter.

Capitol Tunneling also provides the single-pass and two-pass methods of machine mine tunneling. Machine mining utilizes a Tunnel Boring Machine (TBM) to mechanically excavate the face of the tunnel. TBM’s are typically used on larger diameter, longer runs where the expense of these monstrous machines can be absorbed over a larger quantity of tunnel excavation Utilizing equipment we have acquired over the years, as well as several longstanding relationships with various machine manufacturers, Capitol Tunneling is able to custom fit a machine to nearly any application. We have the expertise and know how to trenchlessly navigate your tunnel from start to finish, on line…on grade…and on time.

At Capitol Tunneling, we specialize in both hard rock and soft ground boring. Our fleet of 13 boring machines, ranging in size from 24-inch to 84-inch diameter, enables us to drill and install casings anywhere from an 8-inch diameter hole to a 96-diameter hole. We have more than 8,000 linear feet of auger ranging from 8-inch diameter up to 78-inch diameter, to help facilitate your auger boring needs. If we don’t have what you need, that is not a problem; we have the ability to acquire it or build it ourselves.

The latest addition to our fleet is the 84” Michael Byrne Auger boring machine. This monster is the largest built Auger Boring Machine known to the industry. With its impressive 2.2 million lbs. of thrust, powered by a Caterpillar C-9 engine producing 325 horsepower, we now have the capability of boring 96” diameter steel casing. With a combined total weight of 60,620 lbs., this 72-84” machine is guaranteed to not only turn auger, but to turn heads as well.

In addition to numerous Auger Boring Machines and the miles of readily available auger, we also maintain one of the largest assortments of auger cutting heads in the country. We own cutter heads from a variety of quality manufacturers including Michael Byrne Manufacture, Barbco, American Augers, and the Robbins Company. Our pride and joy is the hard rock disc cutting heads that we have in our arsenal that range from 24” to 74” in diameter. These specialized heads, capable of cutting granite rock up to 35,000 psi, are readily available for use on any project in the United States. We pride ourselves on being known throughout the industry for completing difficult hard rock bores on critical lines and grades. Our specialized crews have installed more than 750,000 feet of pipe ranging from 8 inches to 78 inches in diameter, using a combination of auger boring and pipe jacking methods, installing each casing on line….on grade…and on time.

With the ability to jack concrete pipes ranging in diameter from 36 inches to 120 inches, Capitol Tunneling brings a great deal of pipe jacking experience to any project. Whether it is steel casing, RCP, PCCP, VCP, or FRPPFP, Capitol Tunneling crews have the equipment and knowledge to deliver a successful pipe jacking project.

Pipe Jacking has taken on several different meanings over the past decades. Whereas conventional tunneling or auger boring methods are frequently considered preferred installation methods, occasionally the project needs require the trenchless installation to be performed using Pipe Jacking. With the evolution of materials and the constantly changing equipment technologies, various pipe materials ranging in size from 8” up to 120” can be direct jacked.

Recently, our crews completed the first ever RCP box culvert installation in Dayton Ohio utilizing specially modified pipe jacking equipment. Because of the required cross section flow area, and because of low overhead clearance under existing utilities, the only choice was to direct jack the concrete box culvert in place of a larger diameter concrete pipe. Our crews were able to complete this working 24 hours per day in 8 days with no issues during installation. Yet another successful installation that was on line…on grade…and on time.

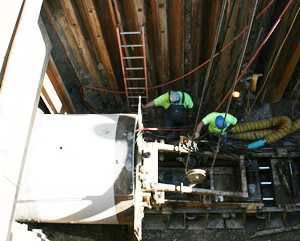

Capitol Tunneling Inc. has extensive shaft sinking experience ranging from 5-foot diameter to 30-foot diameter. Our shaft crews have installed nearly 6000 vertical feet of circular shaft ranging from 5 feet to 30 feet in diameter. We carry an inventory of linear plate shoring and ring beams to readily construct vertical shafts that range from 10 feet to 17 feet in diameter and from 10 feet to 80 feet deep. Do you have a point repair to make in a tight heavily congested area, or a deep manhole to install, or even specific excavations that cannot be constructed with traditional trench shoring techniques? Our shaft sinking expertise is ready and waiting for your call.

Capitol Tunneling, as part of one of our Design/Build contracts, designed and installed 70 vertical feet of 16-foot diameter shaft over a miter section of the failed pipe. The shaft was primarily used for access into the failing pipe. The last 15 feet of the shaft had to be retrofitted to an 18-foot diameter off-set shaft to facilitate encapsulating the entire host pipe. Capitol Tunneling crews and designers fabricated and installed this one of a kind off-set with ease and professionalism. The shaft was structurally sound and maintained its structure integrity for the duration of the project. Again, our crew’s expertise and our firm’s dedication to the completion of a successful project stand out in everything we do.

Capitol Tunneling has the knowledge and equipment to install steel casing using the Pipe Ramming installation method. Using our pipe ramming capabilities, Capitol Tunneling can install casings ranging from 24 to 60-inch diameter in tough ground conditions typically unsuitable for traditional auger boring or tunneling installations. Using this method of installation limits the exposure of settlement due to voids because the spoils are left inside the casing until the completion of the run. Once the casing is in place, the spoils from inside the casing are augured out to make room for the carrier pipe.

Capitol Tunneling owns and operates an 18” TT Technologies Grundoram “Goliath” hammer with collets and casing adapters in the 18”, 24”, 36”, 42”, 48”, 54”, and 60” diameters. Do you need us to go larger? That is not a problem because our crews have extensive experience utilizing TT Technologies 24” Grundoram “Taurus” hammer.

Recently, we successfully installed 200 feet of 60” diameter steel casing under the Little Miami River in Greene County, Ohio, a river that is protected under the laws of Ohio and designated as a Scenic River. We utilized our 18” hammer for the first 120 feet, and then brought in the larger 24” hammer to finish the run. Our 18” hammer also recently installed 165 feet of 54” steel casing on the Dry Run Sanitary Sewer Project for the Cincinnati Metropolitan Sewer District. The loose sand and gravel material made auger boring a risky installation under a busy road. The pipe ramming crews showed up and installed the casing with no incidence of settlement and installed the casing on line…on grade…and on time.

As our drainage infrastructure continues to age, Capitol Tunneling realizes the need to rehabilitate these deteriorating structures. Recently we have undertaken several culvert rehabilitation projects to protect the structural integrity of the host pipe. Culvert rehabilitation covers a vast array of means and methods, and our crews have the documented experience to meet the special needs of this niche market. From slip-lining HDPE carrier pipes into deteriorating host pipes, to completely removing and replacing host structures trenchlessly, our crews are ready and able to do the work.

Recently, Capitol Tunneling was awarded an emergency contract from the Ohio Department of Transportation to remediate a 108” diameter multi-plate structure that had failed under the busy I-90 corridor in Elyria. The collapse had caused I-90 to start to slip and if the culvert was not repaired quickly, a total failure of the pipe and blockage of a major waterway was imminent. CTI crews mobilized to the site and stabilized the failed section of the culvert, then removed and replaced the damaged host pipe with a new tunnel liner plate capable of withstanding the loading. A paved invert was then poured for low flow and the health and safety of the traveling public on I-90 was restored.

In late 2012, the City of Ontario Ohio awarded a contract to Capitol Tunneling to install a HDPE slip-liner pipe into a failing 42” CMP culvert. CTI crews mobilized, prepared the site, installed the liner, and grouted the annulus in record time. The Snap-Tite Product was great to work with and we look forward to working together on additional projects.

Capitol Tunneling is pleased to partner with Grout Solutions to offer a lightweight cellular grout for filling annular spaces. Our cellular grout can also be used for ground stabilization and total pipe abandonment. The cellular grout is significantly lighter than traditional sand grouts which allow us to pump it for further distances. On average, the grout’s unit weight averages 35 lbs per cubic foot, which is 100 lbs. per cubic foot less than traditional sand grouts. This reduces buoyancy concerns when backfilling the annulus between a tunneled or bored casing and the carrier or between a host pipe and a liner pipe in a slip-lining installation. The 200 psi strengths at 28 days provides ample strength to secure carrier pipe without risk of flotation and an engineered fill that has greater strength than the in-situ soils.

The grout mix can be modified to allow for its use in several applications. We primarily use it as an annulus backfill, soil stabilization, ground consolidation, and pipe abandonment. It can also be used as a load reducing/balancing fill over poor soil conditions, as a backfill around bridge culverts or approach slabs, underground voids, structure, or cavern fills, as an insulator, and sub-base for landscaping applications. The grout can be made to be permeable or non-permeable. Installation of the grout can be either by gravity filling or the mix is pump-able using progressive cavity pumps.

All of Capitol Tunneling’s crews have been trained and are able to perform the grouting operation. Call us today to discuss how our grouting expertise can help you.

We know that not all project requirements are black and white, and occasionally that “special” project will require a contractor to think outside the box. At Capitol Tunneling, we love the challenge and risk of just these types of projects. We offer Design/Build capabilities to complete those projects that just don’t fit the mould. From culvert rehabilitation to shaft installations, from tunneling to auger boring, we can offer a Design/Build option to an owner who otherwise does not know where or how to start. We have an Engineer on staff and a team of experienced project managers and superintendents that can team up with other outside design firms to provide a project that meets and exceeds the owner’s needs.

Recent Design/Build projects include both the Newport Pavilion 174” Storm Sewer Repair and Newport Pavilion 72” pipe repair in Newport Kentucky, the ODOT I-90 Emergency Culvert Failure in Elyria Ohio, and the Kalamazoo Nature Center 120” Pedestrian Tunnel under CSX in Kalamazoo Michigan.

Capitol Tunneling also offers educational assistance to owners and engineering firms during the project development stages. We advise of feasibility, means and methods, and perform risk assessments to aid in the successful design of future projects. Our theory is simple: let’s make the project a team effort from the early design phase, all the way through to the completed project.

Capitol Tunneling maintains a fleet of specialized tunneling equipment (tunneling shields) and auger boring equipment that are all available for rent. We can also custom build equipment for your special project requirements. We pride ourselves on the quality of our fleet. We offer rental of our equipment on a weekly and monthly basis. Equipment available for rent includes:

- Hydraulically Driven Tunneling Shields ranging from 48” to 192” in diameter

- 1 ½ Ton Electric Locomotives on 18 gauge and 24 gauge rail

- Dump cars on 12 gauge, 18 gauge, or 24 gauge rail

- CSX and N&S Approved Rail Supports

- 12 gauge, 18 gauge, 24 gauge tunnel track (including California switches)

- Auger Boring Machines – 24”, 30”, 36” (3), 42”, 48” (3), 60” (2), and 84”

- Augers on 2 ½”, 3”, 4”, and 5” hex ranging from 6” to 78” diameter

- Robbins SBU-A Hard Rock Cutting heads – 24” to 72” in diameter

- Robbins SBU-M Hard Rock cutting head – 60” diameter with VFD and 24” invert casing/auger

- Assorted dirt and soft rock cutter heads ranging from 6” to 78” diameter

- Truck B-30 Mobile Drill for Geotechnical exploration ( Operator and Drill helper Required)

- Pipe Jacking Stations

- Unit Cranes with clam buckets ( Operator required)

- Trench shoring including Circular shaft Liner plates, Trench boxes with height adaptors

The list above represents a shorter list of equipment we have available for rent or purchase. If you don’t see what you need, contact us by phone or email. We will be happy to discuss our full line of equipment. If we don’t have what you need, or you need a customized piece of equipment, we can custom fabricate that for you as well.

Capitol Tunneling offers extensive experience in both conventional and machine mined tunneling. Conventional tunneling, also known as hand mine tunneling, is commonly used to tunnel through soil, rock and fill. Tunnel installations using the hand mining methods are ideal for shorter, smaller diameter tunnels that don’t justify the expense of mobilizing a larger scale Tunnel Boring Machine to perform the work. Often, we still utilize specialized hydraulic tunneling shields to provide shoring and safety to both the traveling public as well as the hard working Capitol Tunneling employees diligently working to drive the tunnel. Since its inception, Capitol Tunneling crews have installed more than 125,000 feet of hand-mine tunnel, ranging from 4 feet to 18 feet in diameter.

Capitol Tunneling also provides the single-pass and two-pass methods of machine mine tunneling. Machine mining utilizes a Tunnel Boring Machine (TBM) to mechanically excavate the face of the tunnel. TBM’s are typically used on larger diameter, longer runs where the expense of these monstrous machines can be absorbed over a larger quantity of tunnel excavation Utilizing equipment we have acquired over the years, as well as several longstanding relationships with various machine manufacturers, Capitol Tunneling is able to custom fit a machine to nearly any application. We have the expertise and know how to trenchlessly navigate your tunnel from start to finish, on line…on grade…and on time.

At Capitol Tunneling, we specialize in both hard rock and soft ground boring. Our fleet of 13 boring machines, ranging in size from 24-inch to 84-inch diameter, enables us to drill and install casings anywhere from an 8-inch diameter hole to a 96-diameter hole. We have more than 8,000 linear feet of auger ranging from 8-inch diameter up to 78-inch diameter, to help facilitate your auger boring needs. If we don’t have what you need, that is not a problem; we have the ability to acquire it or build it ourselves.

The latest addition to our fleet is the 84” Michael Byrne Auger boring machine. This monster is the largest built Auger Boring Machine known to the industry. With its impressive 2.2 million lbs. of thrust, powered by a Caterpillar C-9 engine producing 325 horsepower, we now have the capability of boring 96” diameter steel casing. With a combined total weight of 60,620 lbs., this 72-84” machine is guaranteed to not only turn auger, but to turn heads as well.

In addition to numerous Auger Boring Machines and the miles of readily available auger, we also maintain one of the largest assortments of auger cutting heads in the country. We own cutter heads from a variety of quality manufacturers including Michael Byrne Manufacture, Barbco, American Augers, and the Robbins Company. Our pride and joy is the hard rock disc cutting heads that we have in our arsenal that range from 24” to 74” in diameter. These specialized heads, capable of cutting granite rock up to 35,000 psi, are readily available for use on any project in the United States. We pride ourselves on being known throughout the industry for completing difficult hard rock bores on critical lines and grades. Our specialized crews have installed more than 750,000 feet of pipe ranging from 8 inches to 78 inches in diameter, using a combination of auger boring and pipe jacking methods, installing each casing on line….on grade…and on time.

With the ability to jack concrete pipes ranging in diameter from 36 inches to 120 inches, Capitol Tunneling brings a great deal of pipe jacking experience to any project. Whether it is steel casing, RCP, PCCP, VCP, or FRPPFP, Capitol Tunneling crews have the equipment and knowledge to deliver a successful pipe jacking project.

Pipe Jacking has taken on several different meanings over the past decades. Whereas conventional tunneling or auger boring methods are frequently considered preferred installation methods, occasionally the project needs require the trenchless installation to be performed using Pipe Jacking. With the evolution of materials and the constantly changing equipment technologies, various pipe materials ranging in size from 8” up to 120” can be direct jacked.

Recently, our crews completed the first ever RCP box culvert installation in Dayton Ohio utilizing specially modified pipe jacking equipment. Because of the required cross section flow area, and because of low overhead clearance under existing utilities, the only choice was to direct jack the concrete box culvert in place of a larger diameter concrete pipe. Our crews were able to complete this working 24 hours per day in 8 days with no issues during installation. Yet another successful installation that was on line…on grade…and on time.

Capitol Tunneling Inc. has extensive shaft sinking experience ranging from 5-foot diameter to 30-foot diameter. Our shaft crews have installed nearly 6000 vertical feet of circular shaft ranging from 5 feet to 30 feet in diameter. We carry an inventory of linear plate shoring and ring beams to readily construct vertical shafts that range from 10 feet to 17 feet in diameter and from 10 feet to 80 feet deep. Do you have a point repair to make in a tight heavily congested area, or a deep manhole to install, or even specific excavations that cannot be constructed with traditional trench shoring techniques? Our shaft sinking expertise is ready and waiting for your call.

Capitol Tunneling, as part of one of our Design/Build contracts, designed and installed 70 vertical feet of 16-foot diameter shaft over a miter section of the failed pipe. The shaft was primarily used for access into the failing pipe. The last 15 feet of the shaft had to be retrofitted to an 18-foot diameter off-set shaft to facilitate encapsulating the entire host pipe. Capitol Tunneling crews and designers fabricated and installed this one of a kind off-set with ease and professionalism. The shaft was structurally sound and maintained its structure integrity for the duration of the project. Again, our crew’s expertise and our firm’s dedication to the completion of a successful project stand out in everything we do.

Capitol Tunneling has the knowledge and equipment to install steel casing using the Pipe Ramming installation method. Using our pipe ramming capabilities, Capitol Tunneling can install casings ranging from 24 to 60-inch diameter in tough ground conditions typically unsuitable for traditional auger boring or tunneling installations. Using this method of installation limits the exposure of settlement due to voids because the spoils are left inside the casing until the completion of the run. Once the casing is in place, the spoils from inside the casing are augured out to make room for the carrier pipe.

Capitol Tunneling owns and operates an 18” TT Technologies Grundoram “Goliath” hammer with collets and casing adapters in the 18”, 24”, 36”, 42”, 48”, 54”, and 60” diameters. Do you need us to go larger? That is not a problem because our crews have extensive experience utilizing TT Technologies 24” Grundoram “Taurus” hammer.

Recently, we successfully installed 200 feet of 60” diameter steel casing under the Little Miami River in Greene County, Ohio, a river that is protected under the laws of Ohio and designated as a Scenic River. We utilized our 18” hammer for the first 120 feet, and then brought in the larger 24” hammer to finish the run. Our 18” hammer also recently installed 165 feet of 54” steel casing on the Dry Run Sanitary Sewer Project for the Cincinnati Metropolitan Sewer District. The loose sand and gravel material made auger boring a risky installation under a busy road. The pipe ramming crews showed up and installed the casing with no incidence of settlement and installed the casing on line…on grade…and on time.

As our drainage infrastructure continues to age, Capitol Tunneling realizes the need to rehabilitate these deteriorating structures. Recently we have undertaken several culvert rehabilitation projects to protect the structural integrity of the host pipe. Culvert rehabilitation covers a vast array of means and methods, and our crews have the documented experience to meet the special needs of this niche market. From slip-lining HDPE carrier pipes into deteriorating host pipes, to completely removing and replacing host structures trenchlessly, our crews are ready and able to do the work.

Recently, Capitol Tunneling was awarded an emergency contract from the Ohio Department of Transportation to remediate a 108” diameter multi-plate structure that had failed under the busy I-90 corridor in Elyria. The collapse had caused I-90 to start to slip and if the culvert was not repaired quickly, a total failure of the pipe and blockage of a major waterway was imminent. CTI crews mobilized to the site and stabilized the failed section of the culvert, then removed and replaced the damaged host pipe with a new tunnel liner plate capable of withstanding the loading. A paved invert was then poured for low flow and the health and safety of the traveling public on I-90 was restored.

In late 2012, the City of Ontario Ohio awarded a contract to Capitol Tunneling to install a HDPE slip-liner pipe into a failing 42” CMP culvert. CTI crews mobilized, prepared the site, installed the liner, and grouted the annulus in record time. The Snap-Tite Product was great to work with and we look forward to working together on additional projects.

Capitol Tunneling is pleased to partner with Grout Solutions to offer a lightweight cellular grout for filling annular spaces. Our cellular grout can also be used for ground stabilization and total pipe abandonment. The cellular grout is significantly lighter than traditional sand grouts which allow us to pump it for further distances. On average, the grout’s unit weight averages 35 lbs per cubic foot, which is 100 lbs. per cubic foot less than traditional sand grouts. This reduces buoyancy concerns when backfilling the annulus between a tunneled or bored casing and the carrier or between a host pipe and a liner pipe in a slip-lining installation. The 200 psi strengths at 28 days provides ample strength to secure carrier pipe without risk of flotation and an engineered fill that has greater strength than the in-situ soils.

The grout mix can be modified to allow for its use in several applications. We primarily use it as an annulus backfill, soil stabilization, ground consolidation, and pipe abandonment. It can also be used as a load reducing/balancing fill over poor soil conditions, as a backfill around bridge culverts or approach slabs, underground voids, structure, or cavern fills, as an insulator, and sub-base for landscaping applications. The grout can be made to be permeable or non-permeable. Installation of the grout can be either by gravity filling or the mix is pump-able using progressive cavity pumps.

All of Capitol Tunneling’s crews have been trained and are able to perform the grouting operation. Call us today to discuss how our grouting expertise can help you.

We know that not all project requirements are black and white, and occasionally that “special” project will require a contractor to think outside the box. At Capitol Tunneling, we love the challenge and risk of just these types of projects. We offer Design/Build capabilities to complete those projects that just don’t fit the mould. From culvert rehabilitation to shaft installations, from tunneling to auger boring, we can offer a Design/Build option to an owner who otherwise does not know where or how to start. We have an Engineer on staff and a team of experienced project managers and superintendents that can team up with other outside design firms to provide a project that meets and exceeds the owner’s needs.

Recent Design/Build projects include both the Newport Pavilion 174” Storm Sewer Repair and Newport Pavilion 72” pipe repair in Newport Kentucky, the ODOT I-90 Emergency Culvert Failure in Elyria Ohio, and the Kalamazoo Nature Center 120” Pedestrian Tunnel under CSX in Kalamazoo Michigan.

Capitol Tunneling also offers educational assistance to owners and engineering firms during the project development stages. We advise of feasibility, means and methods, and perform risk assessments to aid in the successful design of future projects. Our theory is simple: let’s make the project a team effort from the early design phase, all the way through to the completed project.

Capitol Tunneling maintains a fleet of specialized tunneling equipment (tunneling shields) and auger boring equipment that are all available for rent. We can also custom build equipment for your special project requirements. We pride ourselves on the quality of our fleet. We offer rental of our equipment on a weekly and monthly basis. Equipment available for rent includes:

- Hydraulically Driven Tunneling Shields ranging from 48” to 192” in diameter

- 1 ½ Ton Electric Locomotives on 18 gauge and 24 gauge rail

- Dump cars on 12 gauge, 18 gauge, or 24 gauge rail

- CSX and N&S Approved Rail Supports

- 12 gauge, 18 gauge, 24 gauge tunnel track (including California switches)

- Auger Boring Machines – 24”, 30”, 36” (3), 42”, 48” (3), 60” (2), and 84”

- Augers on 2 ½”, 3”, 4”, and 5” hex ranging from 6” to 78” diameter

- Robbins SBU-A Hard Rock Cutting heads – 24” to 72” in diameter

- Robbins SBU-M Hard Rock cutting head – 60” diameter with VFD and 24” invert casing/auger

- Assorted dirt and soft rock cutter heads ranging from 6” to 78” diameter

- Truck B-30 Mobile Drill for Geotechnical exploration ( Operator and Drill helper Required)

- Pipe Jacking Stations

- Unit Cranes with clam buckets ( Operator required)

- Trench shoring including Circular shaft Liner plates, Trench boxes with height adaptors

The list above represents a shorter list of equipment we have available for rent or purchase. If you don’t see what you need, contact us by phone or email. We will be happy to discuss our full line of equipment. If we don’t have what you need, or you need a customized piece of equipment, we can custom fabricate that for you as well.